Polyurethane

The Most Advanced Material for Sponsons and Inflatable Boats

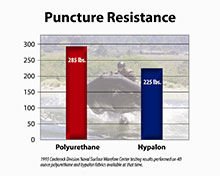

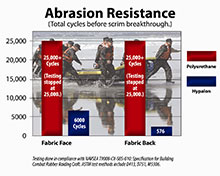

Wing polyurethane has twice the puncture resistance and four times greater abrasion resistance than Hypalon. The expected service life of a polyurethane tube is 7-8 years versus only five for a Hypalon tube.

Testing Polyurethane vs. Hypalon*

| TEST | WELDED POLYURETHANE | GLUED HYPALON |

|---|---|---|

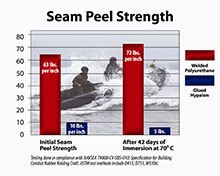

| Seam Peel Strength Initial (minimum req. spec. is 20 lbs./inch) |

63 lbs. per inch | 10 lbs. per inch |

| Seam Peel Strength 42 days of immersion at 700 C (min. req. is 8 lbs./inch) |

72 lbs. per inch | 5 lbs. per inch |

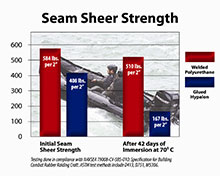

| Seam Shear Strength Initial (minimum req. spec. is 300 lbs./2") |

584 lbs./2" | 408 lbs./2" |

| Seam Shear Strength 42 days of immersion at 700 C (min. req. is 143 lbs./2") |

510 lbs./2" | 167 lbs./2" |

| Abrasion Resistance Material loss after 500 cycles |

Face .003 mg/Back .003 mg | Face .11 mg/Back .99 mg |

| Abrasion Resistance Total cycles before scrim breakthrough |

More than 25,000 cycles (testing stopped at 25,000) |

6000 Face /576 Back |

|

*2011 Industry Testing performed using current generation CRRC industry standard polyurethane vs. hypalon fabrics Testing done in compliance with NAVSEA T9008-CV-SBS-010: Specification for Building Combat Rubber Raiding Craft. ASTM test methods include D413, D751, M5306. |

||

Navy Testing Concludes:

“40 oz/yd Urethane... is CONSIDERABLY STRONGER than the 40 oz/yd Hypalon 1993 Carderock Division Testing Results”

"Tubes constructed of polyurethane coated fabric exhibit better key physical properties than tubes constructed of Hypalon coated fabric...better tensile strength, tearing strength, puncture resistance, coating adhesion, and abrasion resistance.” 2001 Lori L. Fanney, Dept. of the Navy Memorandum

Read the:

Navy's Polyurethane Testing